Paper production at Steinbeis

We’ve been producing recycled paper for over 40 years. We produce energy-efficient, low-emission, resource-saving graphical papers at one of the most modern paper mills in Europe. Not only are we rethinking recycled paper, but also the entire value chain, from procurement to production and disposal. Discover how we are revolutionising paper production and why you should become part of the green revolution for more sustainability.

For those who take environmental protection seriously, there is no alternative to recycled paper.

What is recycled paper?

Recycled papers that carry the Blue Angel are made from 100% reclaimed paper. This involves a wide range of different types of waste paper from private households and from industry and commerce. At Steinbeis Papier, we obtain our waste paper directly from the region and even collect it locally from our customers. This helps us secure a supply of raw materials for our production, and it also avoids long transport journeys and unnecessary carbon emissions.

Unlike recycled papers, conventional papers – known as virgin papers – are made of cellulose. This is obtained from newly felled wood.

Waste paper grades for the production of recycled paper include:

- Sorted household paper

- Variously printed paper from printers

- Sorted waste office paper

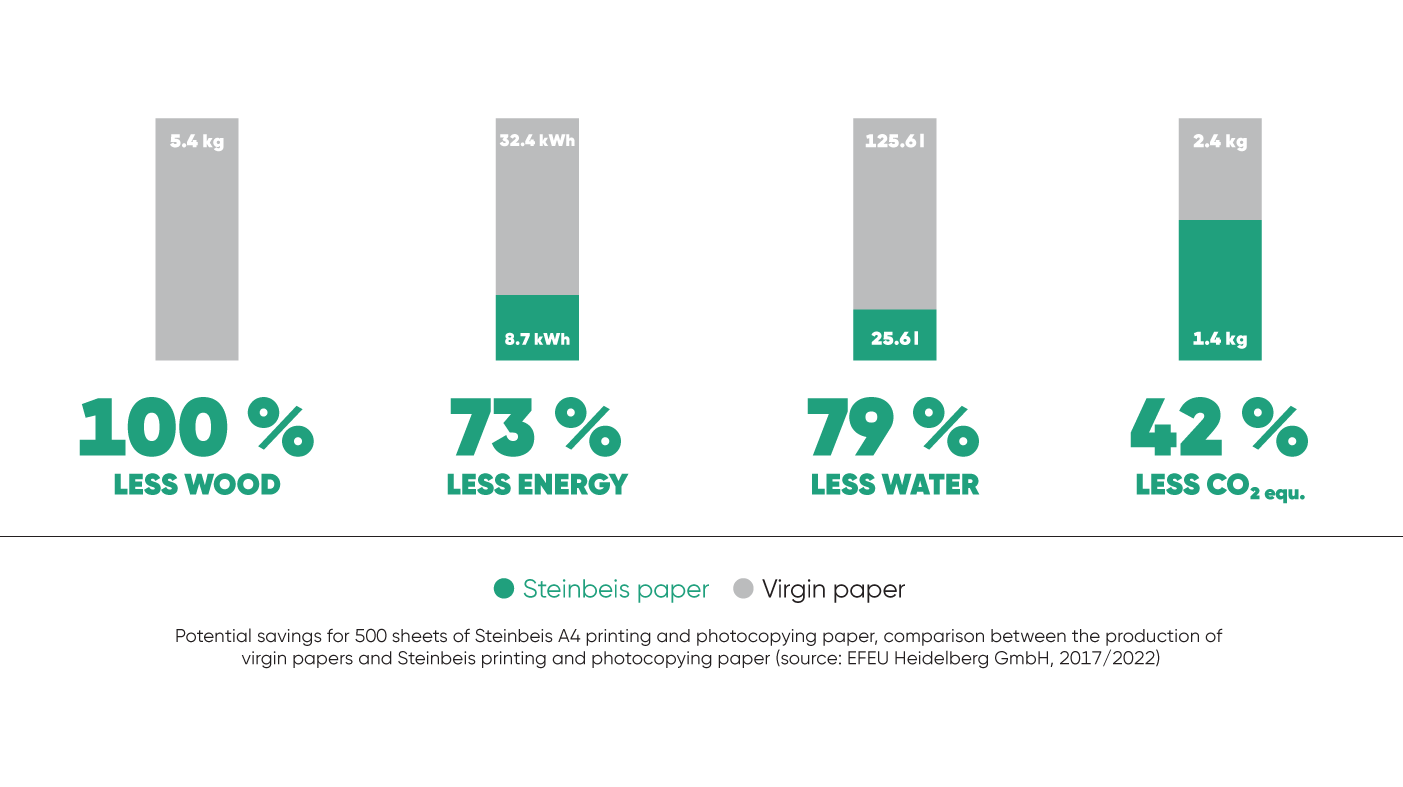

Why is recycled paper good for the environment?

Recycled papers that carry the Blue Angel consist of 100% reclaimed paper. As a result, producing them consumes significantly fewer resources than making virgin papers. Recycled papers protect forests, preserve biodiversity and the climate, and save energy, water and carbon during production. At Steinbeis Papier, we have been producing our recycled papers without wood for over 40 years.

Steinbeis sustainability calculator

Together we can achieve a lot. Calculate how much you can improve your ecological footprint using Steinbeis recycled papers. Save valuable resources such as energy and water, and reduce your carbon emissions.

Calculate savingsHow is recycled paper made?

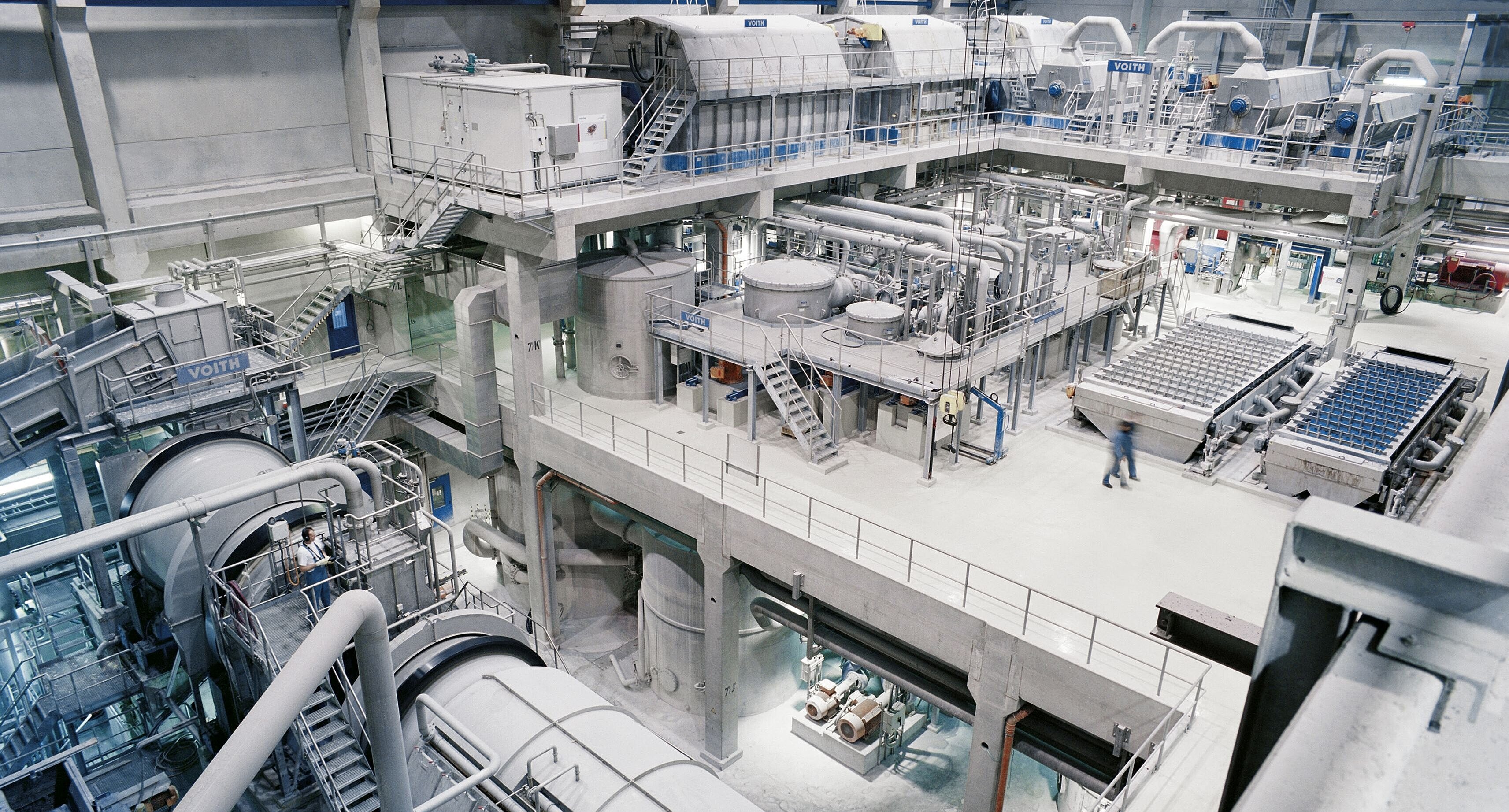

We produce our recycled paper in an energy-efficient, low-emission and resource-saving way in one of the most modern paper mills in Europe.

These are the papers we produce in our paper mill

Recycled papers in the fast lane

Every year we produce more than 300,000 tonnes of graphical papers at our factory in Glückstadt. Once produced, our recycled papers are packed in an environmentally friendly manner and sent on their way to our partners in retail and the printing industry, or directly to our customers. The market share taken up by recycled paper is growing steadily.

The most advanced recycling factory in Europe

When we geared our entire business model towards sustainability in the mid-1970s, we were among the forerunners. Today we are the market leader in graphical recycled paper and produce it in one of the most advanced paper mills in Europe. We have invested over €360 million in recent years, and in 2020 we digitised all our production systems to remain at the forefront of cost leadership and sustainability. We’re rethinking paper – but we’re rethinking the entire production process too.

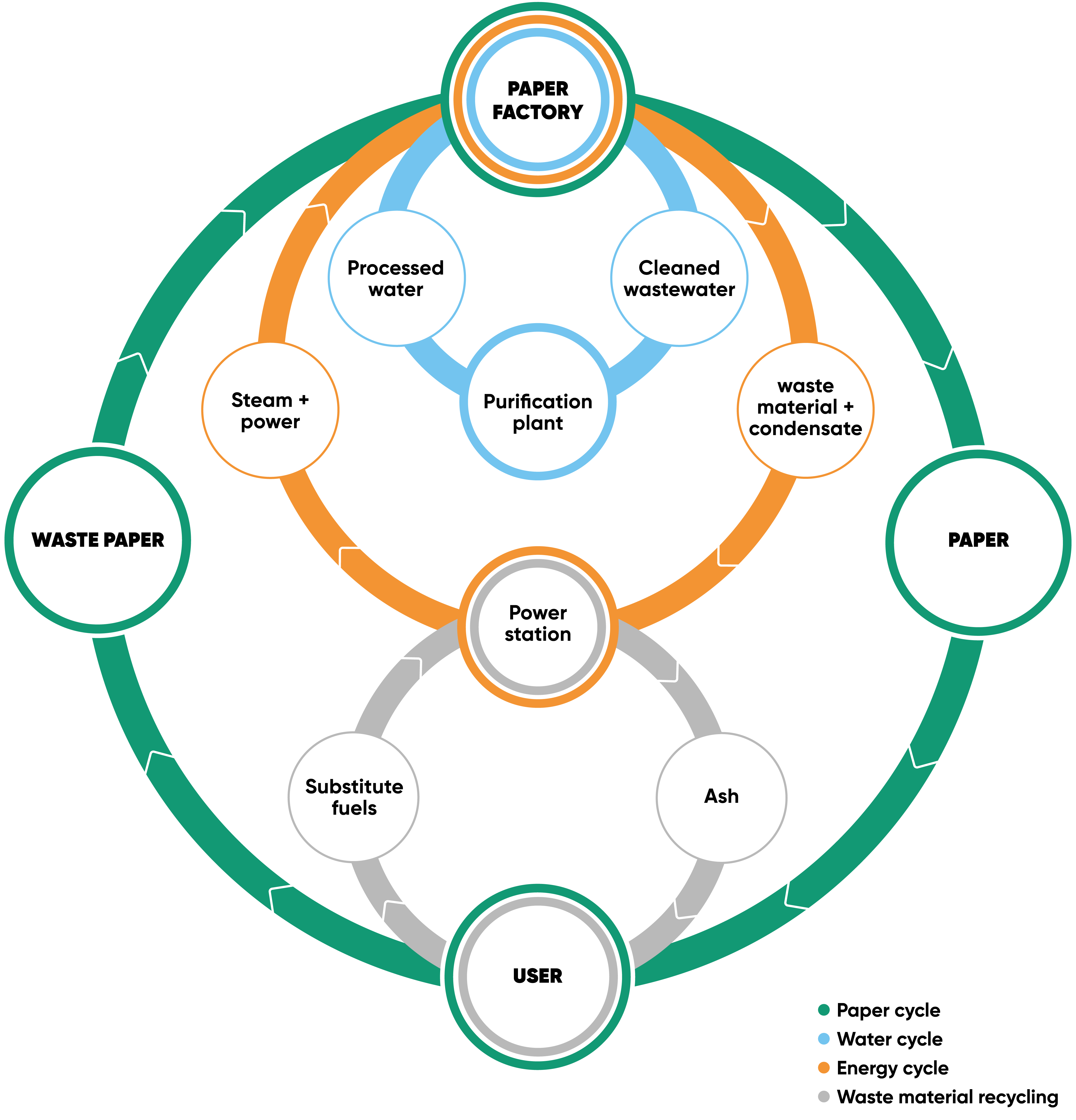

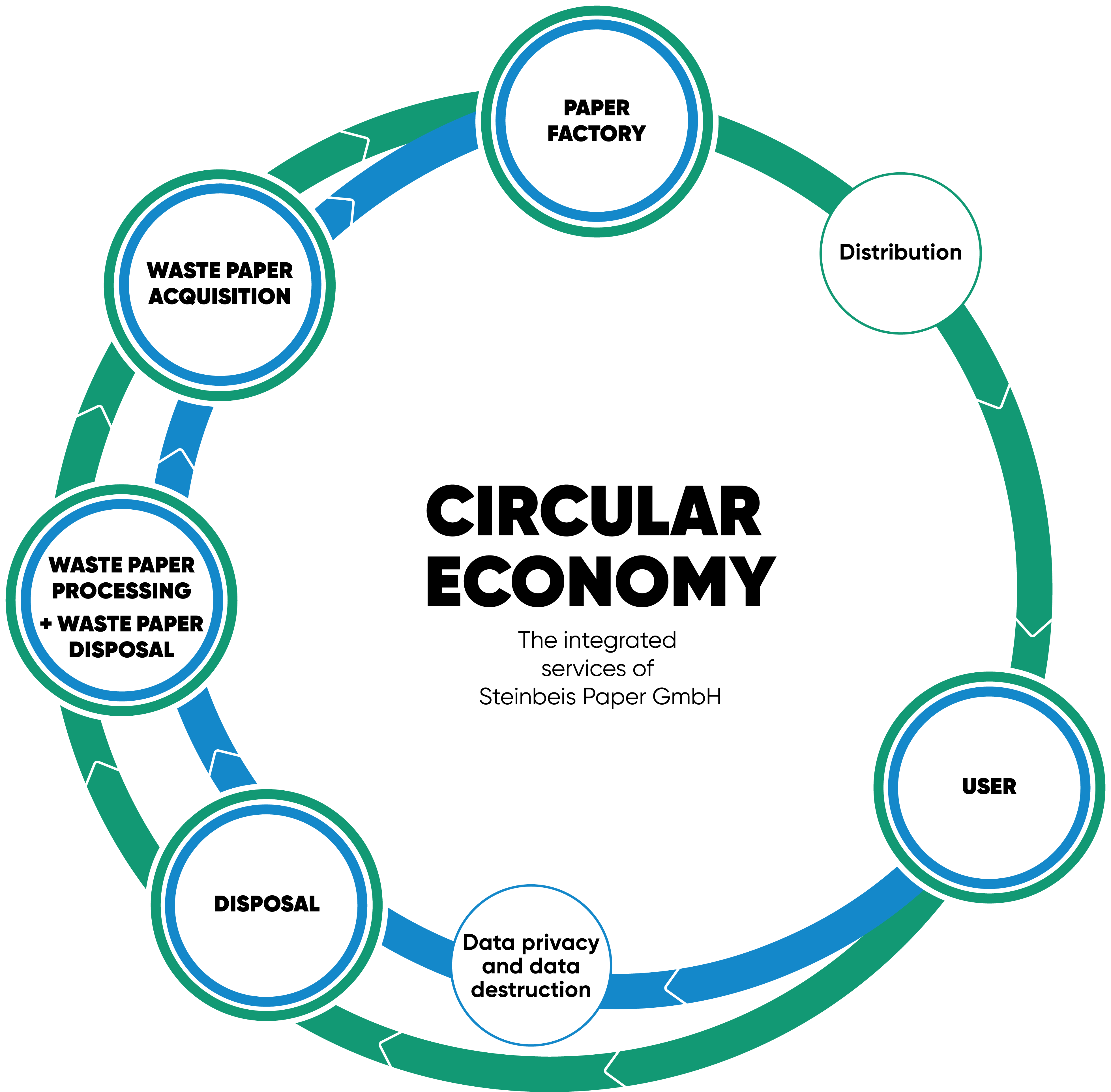

The Steinbeis cycle model

We focus consistently on closed cycle concepts. This enables us to control all of the stages of production and recycling in an ecologically efficient way, while covering most of our own raw material and energy requirements ourselves.

Our paper cycle

- We take care of the whole chain of paper disposal, recycling and production ourselves.

- We procure the waste paper for production locally and feed it directly into recycling and upcycling.

- That way, we keep paper permanently in circulation. The principle being: use, dispose of, refine, recycle.

- ‘Circular Economy – Back-to-Use’ is a service we offer in which we collect waste paper from businesses, ministries and administrative offices and use it to make new paper for them.